Features

• Highest gearbox structure strength ensures minimum rotation vibration.

• High torque and high output speed rate design.

• Thrust bearing coupled in tandem way.

• Precision gear grinding to keep operation noise below 80db.

• Forced lubrication and built in cooling & filter system to ensure excellent heat dissipation.

• Top quality barings form reputed manufacturers like SKF and or ZKL bearings.

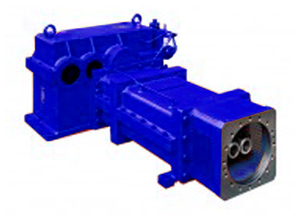

Corresponding to the increasing demand of the twin-screw extruder, P.G DRIVE had developed the series of high performance gearboxes for the twin-screw extruder. Extruders are commonly used equipment used in the industrial production of plastics. Twin Screw extruder’s machines require highly sophisticated gearbox to drive the co-rotating or counter rotating extruder screws. The design requires delivering the highest possible torque evenly in both the screws by utilizing the smallest amount of space. P.G.Drive with its reach experience in the gearing field has now indigenously developed its “TE” series of counter rotating and co rotating gear boxes. The gear unit consists of four sections, the reduction gear unit, thrust housing, distributor gear unit and adapter housing forming the connection with the extruder machine. ( Gearbox for Co-rotating Twin Screw Extruders )

The gearboxes of this series have been developed by featuring high torque and high speed output rate. The series of gearboxes are embedded with excellence heat dissipation and oil lubrication system to perform stable output under heavy-loading force. The axial thrust is supported by an axial roller-type swivel thrust-bearing of the 294..e series, coupled with thrust bearings assembled in tandem way.